<%NUMBERING1%>.<%NUMBERING2%>.<%NUMBERING3%> PRTG Manual: Sensor Factory Sensor

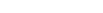

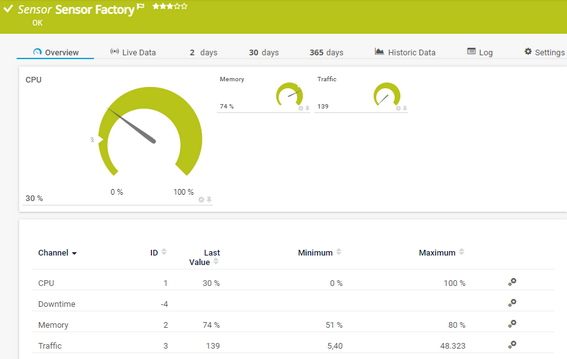

The Sensor Factory sensor lets you monitor entire business processes that involve several components.

You can define one or more channels that combine monitoring results from other sensors or devices. You can create a customized sensor with channels based on data from other sensors ("source sensors").

Samples for usage are:

- Show single channels of one or more sensors in one graph.

- Use the data from single channels of one or more sensors to calculate new values (for example, you can subtract, multiply, and divide).

- Create graphs with data from other sensor channels and add horizontal lines at specific vertical positions.

The Sensor Factory sensor does not show values in the Downtime channel because they cannot be calculated for this sensor.

The Sensor Factory sensor does not show values in the Downtime channel because they cannot be calculated for this sensor.

If you want to create only a cumulated sensor status based on specific source sensors, we recommend that you use the Business Process sensor instead.

If you want to create only a cumulated sensor status based on specific source sensors, we recommend that you use the Business Process sensor instead.

Which channels the sensor actually shows might depend on the monitored device and the sensor setup.

Which channels the sensor actually shows might depend on the monitored device and the sensor setup.

Sensor Factory Sensor

Sensor in Other Languages

Dutch: Sensor Fabriek, French: Capteur combiné, German: Formelsensor, Japanese: センサーファクトリ, Portuguese: Sensor de fórmula, Russian: Фабрика сенсоров, Simplified Chinese: 传感器出厂, Spanish: Sensor Factory

Remarks

Limited to 50 Sensor Channels

PRTG does not officially support more than 50 sensor channels. Depending on the data used with this sensor, you might exceed the maximum number of supported sensor channels. In this case, PRTG tries to display all sensor channels. Be aware, however, that you experience limited usability and performance.

PRTG does not officially support more than 50 sensor channels. Depending on the data used with this sensor, you might exceed the maximum number of supported sensor channels. In this case, PRTG tries to display all sensor channels. Be aware, however, that you experience limited usability and performance.

Add Sensor

The Add Sensor dialog appears when you manually add a new sensor to a device. It only shows the setting fields that are required for creating the sensor. Therefore, you do not see all setting fields in this dialog. You can change (nearly) all settings in the sensor's Settings tab later.

Sensor Settings

On the details page of a sensor, click the Settings tab to change its settings.

Usually, a sensor connects to the IP Address or DNS Name of the parent device on which you created the sensor. See the Device Settings for details. For some sensors, you can explicitly define the monitoring target in the sensor settings. See below for details on available settings.

Usually, a sensor connects to the IP Address or DNS Name of the parent device on which you created the sensor. See the Device Settings for details. For some sensors, you can explicitly define the monitoring target in the sensor settings. See below for details on available settings.

|

|

Sensor Name

|

Enter a meaningful name to identify the sensor. By default, PRTG shows this name in the device tree, as well as in alarms, logs, notifications, reports, maps, libraries, and tickets.

|

Parent Tags

|

Shows Tags that this sensor inherits from its parent device, group, and probe. This setting is shown for your information only and cannot be changed here.

|

Tags

|

Enter one or more Tags, separated by spaces or commas. You can use tags to group sensors and use tag–filtered views later on. Tags are not case sensitive. We recommend that you use the default value.

There are default tags that are automatically predefined in a sensor's settings when you add a sensor. See section Default Tags below.

You can add additional tags to the sensor if you like. Other tags are automatically inherited from objects further up in the device tree. These are visible above as Parent Tags.

It is not possible to enter tags with a leading plus (+) or minus (-) sign, nor tags with parentheses (()) or angle brackets (<>). It is not possible to enter tags with a leading plus (+) or minus (-) sign, nor tags with parentheses (()) or angle brackets (<>).

|

Priority

|

Select a priority for the sensor. This setting determines where the sensor is placed in sensor lists. A sensor with a top priority is at the top of a list. Choose from one star (low priority) to five stars (top priority).

|

Default Tags

factorysensor

|

|

Channel Definition

|

Enter a channel definition for the Sensor Factory sensor. Using a specific syntax, you can refer to data from channels of other sensors here. You can also calculate values. Enter one channel definition for each new channel that you want to add to the Sensor Factory sensor.

For more information, see section Define Sensor Channels below. For more information, see section Define Sensor Channels below.

|

Status Handling

|

Define the behavior of the Sensor Factory sensor if one of the source sensors defined above is in a Down status. In this case, you can set the Sensor Factory sensor either to Down or to Warning status. Choose from:

- Show down status when one or more source sensors are in down status: If at least one source sensor that you use in a channel definition is in a Down status, the Sensor Factory sensor shows a Down status as well until all referred sensors leave this status. While the Sensor Factory sensor is Down, it still shows data of all available sensor channels.

If a lookup definition or an error limit triggers the Down status of the source sensor, the Sensor Factory does not show a Down status. This is because the Sensor Factory should only show this status if it cannot calculate values. If a lookup definition or an error limit triggers the Down status of the source sensor, the Sensor Factory does not show a Down status. This is because the Sensor Factory should only show this status if it cannot calculate values.

- Show warning status when one or more source sensors are in down status: If at least one source sensor that you use in a channel definition is in a Down status, the Sensor Factory sensor shows a Warning status until all referred sensors leave the Down status.

If a lookup definition or an error limit triggers the Down status of the source sensor, the Sensor Factory does not show a Warning status. This is because the Sensor Factory sensor should only show this status if it cannot calculate values. If a lookup definition or an error limit triggers the Down status of the source sensor, the Sensor Factory does not show a Warning status. This is because the Sensor Factory sensor should only show this status if it cannot calculate values.

- Use custom formula: Define the status of the Sensor Factory sensor by adding a status definition in the field below.

|

Status Definition

|

This field is only visible if you enable Use custom formula above. Define when the sensor switches to a Down status. You can use the status() function in combination with Boolean operations. For advanced users, it is also possible to calculate a status value.

For more information, see section Define Sensor Status below. For more information, see section Define Sensor Status below.

|

If a Source Sensor Has No Data

|

Choose how this Sensor Factory sensor reacts if a source sensor referred to in the channel definition does not provide any data (for example, because it is paused or does not exist):

- Do not calculate the channels that use the sensor: For defined channels that use one or more sensors that deliver no data, no data is shown.

- Calculate the channels and use zero as source value: If a source sensor that you use in a channel definition does not deliver any data, zero values are filled in instead. The Sensor Factory sensor calculates the channel value and shows it using these zero values.

If a sensor in the channel of a Sensor Factory sensor has no data, the Sensor Factory sensor always shows a Warning status, no matter which of the above options you select. If a sensor in the channel of a Sensor Factory sensor has no data, the Sensor Factory sensor always shows a Warning status, no matter which of the above options you select.

|

|

|

Primary Channel

|

Select a channel from the list to define it as the primary channel. In the device tree, the last value of the primary channel is always displayed below the sensor's name. The available options depend on what channels are available for this sensor.

You can set a different primary channel later by clicking the pin symbol of a channel on the sensor's Overview tab. You can set a different primary channel later by clicking the pin symbol of a channel on the sensor's Overview tab.

|

Graph Type

|

Define how different channels are shown for this sensor:

- Show channels independently (default): Show a graph for each channel.

- Stack channels on top of each other: Stack channels on top of each other to create a multi-channel graph. This generates a graph that visualizes the different components of your total traffic.

This option cannot be used in combination with manual Vertical Axis Scaling (available in the Sensor Channel Settings settings). This option cannot be used in combination with manual Vertical Axis Scaling (available in the Sensor Channel Settings settings).

|

Stack Unit

|

This field is only visible if you enable Stack channels on top of each other as Graph Type. Select a unit from the list. All channels with this unit are stacked on top of each other. By default, you cannot exclude single channels from stacking if they use the selected unit. However, there is an advanced procedure to do so.

|

Inherited Settings

By default, all of the following settings are inherited from objects that are higher in the hierarchy and should be changed there if necessary. Often, best practice is to change them centrally in the Root group's settings. For more information, see section Inheritance of Settings. To change a setting for this object only, disable inheritance by clicking the button next to inherit from under the corresponding setting name. You then see the options described below.

|

|

Click  to interrupt the inheritance. See section Inheritance of Settings for more information. to interrupt the inheritance. See section Inheritance of Settings for more information.

|

Scanning Interval

|

Select a scanning interval (seconds, minutes, or hours). The scanning interval determines the amount of time that the sensor waits between two scans. You can change the available intervals in the system administration on PRTG on premises installations.

|

If a Sensor Query Fails

|

Define the number of scanning intervals that the sensor has time to reach and check a device again in case a sensor query fails. Depending on the option that you select, the sensor can try to reach and check a device again several times before the sensor shows a Down status. This can avoid false alarms if the monitored device only has temporary issues. For previous scanning intervals with failed requests, the sensor shows a Warning status. Choose from:

- Set sensor to down immediately: Set the sensor to a Down status immediately after the first failed request.

- Set sensor to warning for 1 interval, then set to down (recommended): Set the sensor to a Warning status after the first failed request. If the following request also fails, the sensor shows an error.

- Set sensor to warning for 2 intervals, then set to down: Set the sensor to a Down status only after three consecutively failed requests.

- Set sensor to warning for 3 intervals, then set to down: Set the sensor to a Down status only after four consecutively failed requests.

- Set sensor to warning for 4 intervals, then set to down: Set the sensor to a Down status only after five consecutively failed requests.

- Set sensor to warning for 5 intervals, then set to down: Set the sensor to a Down status only after six consecutively failed requests.

Sensors that monitor via Windows Management Instrumentation (WMI) always wait at least one scanning interval before they show a Down status. It is not possible to immediately set a WMI sensor to a Down status, so the first option does not apply to these sensors. All other options can apply. Sensors that monitor via Windows Management Instrumentation (WMI) always wait at least one scanning interval before they show a Down status. It is not possible to immediately set a WMI sensor to a Down status, so the first option does not apply to these sensors. All other options can apply.

If you define error limits for a sensor's channels, the sensor immediately shows a Down status. No "wait" option applies. If you define error limits for a sensor's channels, the sensor immediately shows a Down status. No "wait" option applies.

If a channel uses lookup values, the sensor immediately shows a Down status. No "wait" options apply. If a channel uses lookup values, the sensor immediately shows a Down status. No "wait" options apply.

|

|

|

You cannot interrupt the inheritance for schedules, dependencies, and maintenance windows. The corresponding settings from the parent objects are always active. However, you can define additional settings here. They are active at the same time as the parent objects' settings. You cannot interrupt the inheritance for schedules, dependencies, and maintenance windows. The corresponding settings from the parent objects are always active. However, you can define additional settings here. They are active at the same time as the parent objects' settings.

|

Schedule

|

Select a schedule from the list. Schedules can be used to monitor for a certain time span (days or hours) every week.

You can create schedules, edit schedules, or pause monitoring for a specific time span. For more information, see section Account Settings—Schedules. You can create schedules, edit schedules, or pause monitoring for a specific time span. For more information, see section Account Settings—Schedules.

Schedules are generally inherited. New schedules are added to existing schedules, so all schedules are active at the same time. Schedules are generally inherited. New schedules are added to existing schedules, so all schedules are active at the same time.

|

Maintenance Window

|

Specify if you want to set up a one-time maintenance window. During a maintenance window, the current object and all child objects are not monitored. They are in a Paused status instead. Choose between:

- Not set (monitor continuously): No maintenance window is set and monitoring is always active.

- Set up a one-time maintenance window: Pause monitoring within a maintenance window. You can define a time span for a monitoring pause below and change it even for a currently running maintenance window.

To terminate a current maintenance window before the defined end date, change the time entry in Maintenance Ends to a date in the past. To terminate a current maintenance window before the defined end date, change the time entry in Maintenance Ends to a date in the past.

|

Maintenance Begins

|

This field is only visible if you enable Set up a one-time maintenance window above. Use the date time picker to enter the start date and time of the maintenance window.

|

Maintenance Ends

|

This field is only visible if you enable Set up a one-time maintenance window above. Use the date time picker to enter the end date and time of the maintenance window.

|

Dependency Type

|

Define a dependency type. You can use dependencies to pause monitoring for an object depending on the status of another object. You can choose from:

- Use parent: Use the dependency type of the parent object.

- Select a sensor: Use the dependency type of the parent object. Additionally, pause the current object if another specific sensor is in a Down status or in a Paused status caused by another dependency.

- Master sensor for parent: Make this sensor the master object for its parent device. The sensor influences the behavior of its parent device: If the sensor is in a Down status, the device is paused. For example, it is a good idea to make a Ping sensor the master object for its parent device to pause monitoring for all other sensors on the device in case the device cannot even be pinged. Additionally, the sensor is paused if the parent group is paused by another dependency.

To test your dependencies, select Simulate Error Status from the context menu of an object that other objects depend on. A few seconds later, all dependent objects are paused. You can check all dependencies under Devices | Dependencies in the main menu bar. To test your dependencies, select Simulate Error Status from the context menu of an object that other objects depend on. A few seconds later, all dependent objects are paused. You can check all dependencies under Devices | Dependencies in the main menu bar.

|

Dependency

|

This field is only visible if you enable Select a sensor above. Click the Search button and use the object selector to select a sensor on which the current object will depend.

|

Dependency Delay (Sec.)

|

This field is only visible if you enable Select a sensor above. Define a time span in seconds for dependency delay.

After the master sensor for this dependency comes back to an Up status, monitoring of the dependent objects is additionally delayed by the defined time span. This can help avoid false alarms, for example, after a server restart, by giving systems more time for all services to start up. Enter an integer value.

This setting is not available if you set this sensor to Use parent or to be the Master sensor for parent. In this case, define delays in the parent Device Settings or in its parent Group Settings. This setting is not available if you set this sensor to Use parent or to be the Master sensor for parent. In this case, define delays in the parent Device Settings or in its parent Group Settings.

|

|

|

Click  to interrupt the inheritance. See section Inheritance of Settings for more information. to interrupt the inheritance. See section Inheritance of Settings for more information.

|

User Group Access

|

Define the user groups that have access to the selected object. A table with user groups and types of access rights is shown. It contains all user groups from your setup. For each user group, you can choose from the following access rights:

- Inherited: Use the access rights settings of the parent object.

- None: Users in this group cannot see or edit the object. The object neither shows up in lists nor in the device tree. Exception: If a child object is visible to the user, the object is visible in the device tree but it cannot be accessed.

- Read: Users in this group can see the object and review its monitoring results.

- Write: Users in this group can see the object, review its monitoring results, and edit its settings. They cannot edit access rights settings.

- Full: Users in this group can see the object, review its monitoring results, edit its settings, and edit access rights settings.

You can create new user groups in the System Administration—User Groups settings. To automatically set all objects further down in the hierarchy to inherit this object's access rights, set a check mark for the Revert children's access rights to inherited option.

For more details on access rights, see section User Access Rights. For more details on access rights, see section User Access Rights.

|

Define Sensor Channels

The channels of a Sensor Factory sensor are controlled by the Channel Definition text field. Using a special syntax, you can refer to other sensor channels, calculate values, and add horizontal lines. You can define Sensor Factory sensor channels using data from any other sensor's channels on your PRTG server.

Example Example

You see a definition of two Sensor Factory sensor channels. Both use the channel() function that collects data from the channels of other sensors in your monitoring and displays them:

#1:Local Probe Health

channel(1001,0)

#2:Local Traffic Out[kbit]

channel(1004,1)

The first channel of the Sensor Factory sensor (#1) collects data from the Health channel (ID 0) of the Probe Health sensor (ID 1001) running on the probe device. The second channel (#2) collects data from the Traffic out channel (ID 1) of a traffic sensor (ID 1004) measuring the system's local network card. Both channels are shown together in the Sensor Factory sensor's data tables and graphs.

|

The basic syntax for a Sensor Factory sensor channel definition looks like this:

#<id>:<name>[<unit>]

<formula>

For each channel, one section is used. A section begins with the number sign (#). Function names in formulas are not case sensitive.

The parameters are:

- <id> is the ID of the Sensor Factory sensor's channel. It must be a unique number that is greater than 0.

- <name> is the name of the Sensor Factory sensor's channel (displayed in graphs and tables).

- [<unit>] is an optional unit description for the Sensor Factory sensor's channel (for example, bytes). If you do not provide a unit, the Sensor Factory sensor automatically selects a suitable unit string (recommended).

- <formula> contains the formula to calculate the Sensor Factory sensor's channel. For the formula, you can use the following functions: channel(), min(), max(), avg(), or percent().

Define Sensor Channels—Formula Calculations

Within a formula, the following elements are allowed to perform calculations with the values that are returned by one or more functions.

- Basic operations: + (add), - (subtract), * (multiply), / (divide)

Example: 3 + 5 * 2

- Brackets: ( )

Example: 3 * (2 + 6)

- Compare: = (equal), <> (not equal), > (greater), < (less), >= (greater or equal), <= (less or equal)

If the comparison resolves to true, the value is 10,000. If false, the value is 0. For delta sensors, the speed is compared.

Example Example

You see a Sensor Factory channel definition with calculation.

#1:Traffic Total x Minus Traffic Out y

( channel(2001,-1) - channel(1004,1) ) * 2

This full channel definition results in a Sensor Factory sensor that shows a calculation with values from two channels (channel IDs -1 and 1) of two traffic sensors (sensor IDs 2001 and 1004). The returned values are subtracted and then multiplied by two.

|

Channels can be gauge values (for example, ping ms) or delta values (for example, traffic kbit/s). Not all combinations are allowed in a formula.

When performing percentage calculation, use the percent() Function to make sure you obtain the expected values!

When performing percentage calculation, use the percent() Function to make sure you obtain the expected values!

There are calculations you cannot do:

- You cannot add or subtract a delta from a gauge channel (and vice versa).

- You cannot multiply two delta channels.

- You cannot compare a delta with a gauge channel.

- You cannot use a channel of (another) Sensor Factory sensor channel in the formula.

Define Sensor Channels—channel() Function

The channel() function allows the Sensor Factory sensor to read the data from a channel of a source sensor. The syntax is:

channel(<sensorId>,<channelId>)

The parameters are:

- <sensorId> is the ID of the source sensor. It is displayed on the sensor's Overview tab in the page header bar.

- <channelId> is the ID of the source sensor channel. It is displayed in the respective field of the channel settings.

Example Example

channel(2001,2)

This function reads the data from channel ID 2 of the source sensor with the ID 2001.

#1:Sample

channel(2001,2)

This full channel definition reads the data from channel ID 2 of the source sensor with the ID 2001 and displays it in the first Sensor Factory sensor channel (#1), without any additional calculations.

|

Define Sensor Channels—min() and max() Functions

The min() and max() functions return the minimum or maximum of two values. The syntax is:

min(<a>,<b>)

max(<a>,<b>)

Values for <a> and <b> are either numbers or channel() functions.

Examples Examples

min(10,5)

This function returns 5, because this is the smaller value out of 10 and 5.

min( channel(2001,1),channel(2002,1) )

This function returns the minimum of the values of channel 1 of the source sensor with ID 2001 and channel 1 of the source sensor with ID 2002.

|

Define Sensor Channels—avg() Function

The avg() function returns the average of the two values. This equals: (a+b) / 2. The syntax is:

avg(<a>,<b>)

Values for <a> and <b> are either numbers or channel() functions.

Examples Examples

avg(20,10)

This function returns 15: (20+10) / 2 = 15.

avg( channel(2001,1),channel(2002,1) )

This function returns the average of channel 1 of the source sensor with ID 2001 and channel 1 of the source sensor with ID 2002.

|

Define Sensor Channels—percent() Function

The percent() function calculates the percent value of two specified values, for example, a channel and a fixed value. The syntax is:

percent(<source>,<maximum>[,<unit>])

The parameters are:

- <source> is the value the percent is calculated for. This is usually a channel() function.

- <maximum> is the limit value used for the percent calculation.

- [<unit>] is an optional unit the maximum is provided in. You can use constants with this function (see Constants section below for a list). This can be used for absolute values (for example, Ping sensors) or calculated delta values (for example, traffic sensors). If no unit is provided, 1 is used.

The sensor adds the unit string % automatically.

The sensor adds the unit string % automatically.

PRTG calculates: <source> / <maximum> * <unit> * 100

Examples Examples

#1:Usage Traffic In

percent(channel(2001,0),100,kilobit)

#2:Usage Traffic Out

percent(channel(2001,1),100,kilobit)

This full channel definition results in a Sensor Factory sensor that shows two channels of a traffic sensor (sensor ID 2001): Traffic in (channel ID 0) and traffic out (channel ID 1). The Sensor Factory sensor displays the values % of maximum bandwidth (100 kilobit/second).

#1:Ping %

percent(channel(2002,0),200)

This full channel definition results in a Sensor Factory sensor that shows the Ping Time channel (channel ID 0) of a Ping sensor (sensor ID 2002). The sensor displays the values as a percentage of 200 ms.

|

Define Sensor Channels—Horizontal Lines

You can add lines to the graph using a formula without the channel() function. Use a fixed value instead. The syntax is:

#<id>:<name>[<unit>]

<value>

The parameters are:

- <id> is the ID of the Sensor Factory sensor's channel and must be a unique number greater than 1. Although the Sensor Factory sensor does not show a horizontal line as a channel, the ID has to be unique.

- <name> is the name of the Sensor Factory sensor's channel. PRTG does not display this name in graphs and tables, but you can use it as a comment to describe the nature of the line.

- [<unit>] is an optional unit description (for example, kbit/s). If you do not provide a unit, PRTG automatically applies the line to the scale of the first Sensor Factory sensor's channel. If your Sensor Factory sensor uses different units, provide a unit to make sure the line is added for the right scale. Enter the unit exactly as shown in your graph's legend. If you enter a unit that does not yet exist in your graph, a new scale is added automatically.

- <value> contains a number defining where the line is shown in the graph.

Examples Examples

#5:Line at 100ms [ms]

100

This channel definition results in a graph that shows a horizontal line at the value of 100 on the ms scale.

#6:Line at 2 Mbit/s [kbit/s]

2000

This channel definition results in a graph that shows a horizontal line at the value of 2000 on the kbit/s scale.

#1:Ping Time

channel(2002,0)

#2:Line at 120ms [ms]

120

This full channel definition results in a Sensor Factory sensor that shows the Ping Time channel (channel ID 0) of a Ping sensor (sensor ID 2002). Additionally, the sensor graphs show a horizontal line at 120 ms.

|

Define Sensor Channels—Constants

The following constants are defined and can be used in calculations:

- one = 1

- kilo = 1000

- mega = 1000 * kilo

- giga = 1000 * mega

- tera = 1000 * giga

- byte = 1

- kilobyte = 1024

- megabyte = 1024 * kilobyte

- gigabyte = 1024 * megabyte

- terabyte = 1024 * gigabyte

- bit = 1/8

- kilobit = kilo / 8

- megabit = mega / 8

- gigabit = giga / 8

- terabit = tera / 8

Define Sensor Status—status() Function

You can control the status of a Sensor Factory sensor via the Status Definition text field if you enable the custom formula option in the Sensor Settings. Using a special syntax, you can define when the Sensor Factory sensor changes to a Down status. In all other cases, the sensor is in an Up status. The syntax is:

status(sensorID) <boolean> status(sensorID)

The parameters are:

- <sensorId> is the ID of the source sensor that you want to check the status of. It is displayed on the sensor's Overview tab in the page header bar.

- <boolean> is one of the Boolean operators AND, OR, or NOT. If the resulting expression is true, the Sensor Factory sensor changes to a Down status.

Examples Examples

status(2031) AND status(2044)

This changes the Sensor Factory sensor to a Down status if both source sensors, with IDs 2031 and 2044, are Down. Otherwise the Sensor Factory sensor shows an Up status.

status(2031) OR status(2044)

This changes the Sensor Factory sensor to a Down status if at least one of the source sensors with ID 2031 or ID 2044 is Down. Otherwise the Sensor Factory sensor shows an Up status.

status(2031) AND NOT status(2044)

This changes the Sensor Factory sensor to a Down status if the source sensor with ID 2031 is Down, but the source sensor with ID 2044 is not in a Down status. Otherwise the Sensor Factory sensor shows an Up status.

A status() function with NOT has to be connected with AND or OR if it is combined with other status() functions: A status() function with NOT has to be connected with AND or OR if it is combined with other status() functions:

status(sensorID) AND NOT status(sensorID)

status(sensorID) OR NOT status(sensorID)

( status(2031) AND status(2044) ) OR status(2051)

This changes the Sensor Factory sensor to a Down status if both the source sensor with ID 2031 and the source sensor with ID 2044 is Down, or if the source sensor with ID 2051 is Down. Otherwise the Sensor Factory sensor shows an Up status.

|

Additionally, the following elements are allowed to perform calculations and comparisons with the values that are returned by the status functions:

- Basic operations: + (add), - (subtract), * (multiply), / (divide)

Example: 3 + 5 * 2

- Brackets: ( )

Example: 3 * (2 + 6)

- Compare: = (equal), <> (not equal), > (greater), < (less), >= (greater or equal), <= (less or equal)

If the comparison resolves to true, the value is 10,000. If false, the value is 0. For delta sensors, the speed is compared.

Internally, the status() function returns the downtime channel of the source sensor in hundreds of percent (10,000 = 100%).

- true corresponds to a value of 10,000, which is a Down status.

- false corresponds to a value of 0, which is an Up status.

If you understand this, you can use more complex formulas.

Example Example

( status(1031) + status(1032) + status(1033) + status(1034) ) >= 20000

This changes the Sensor Factory sensor to a Down status if at least any two of the source sensors with IDs 1031, 1032, 1033, or 1034 are Down. Otherwise the Sensor Factory sensor shows an Up status.

|

You can also use the status() function in channel definitions. Using this functionality, it is possible, for example, to display the numeric status value of source sensors in a Sensor Factory sensor channel.

You can also use the status() function in channel definitions. Using this functionality, it is possible, for example, to display the numeric status value of source sensors in a Sensor Factory sensor channel.

Using Sensor Factory Sensors in a Cluster Setup

If you run PRTG in Clustering mode, note the following:

- If you add a Sensor Factory sensor underneath the Cluster Probe, and in the Sensor Factory formula you refer to a channel of a source sensor running on the Cluster Probe as well, the Sensor Factory sensor shows the data of all cluster nodes for this sensor channel.

- If you add a Sensor Factory sensor underneath the Local Probe, and in the Sensor Factory formula you refer to a channel of a sensor running on the Cluster Probe, the Sensor Factory sensor only shows data of the primary master node for this sensor channel.

More

Knowledge Base: Can you help me understand when the Sensor Factory sensor changes to a down status and why?

Knowledge Base: What can I do with the Sensor Factory sensors of PRTG?

Knowledge Base: How can I monitor the overall status of the business process "Email"?

Paessler Blog: Monitoring Business Processes: Transformation of Technical Outages to the Real Business Impact

Video Tutorial: Sensor Factory Sensor

Edit Sensor Channels

To change display settings and limits, switch to the sensor's Overview tab and click the gear icon of a specific channel.

For detailed information, see the Sensor Channel Settings.

For detailed information, see the Sensor Channel Settings.

Notification Triggers

Click the Notification Triggers tab to change notification triggers. For detailed information, see section Sensor Notification Triggers Settings.

Others

For more general information about settings, see section Object Settings.

Sensor Settings Overview

For information about sensor settings, see the following sections: